Sensors: applications and types

A sensor is a device that detects or measures changes in the physical environment and converts this information into an electrical or digital signal. Changes can include temperature, pressure, light, motion, among others. Sensors are used in a wide range of applications, from consumer electronics, such as smartphones and smartwatches, to industrial applications, such as process control systems and environmental monitoring. They allow for the collection of data from the environment for processing, analysis, and control.

There is an extremely wide variety of sensors, with three main groups standing out:

- Modulating analog sensors

- Generating analog sensors

- Digital sensors

There are some other sensors that are difficult to classify into a group. For example, in some cases, it is difficult to differentiate them from an interface, and it may be the usage that defines their classification. Others are intertwined with actuators, complementing each other, also making classification difficult in this sense.

Modulating analog sensors

Modulating analog sensors are classified based on the electrical parameter that changes in response to variations in the input physical magnitude. In this way, we can have resistive, capacitive, inductive, etc. sensors.

Resistive

Resistive sensors operate by altering the resistance of a conductor (or semiconductor) in response to changes in a specific physical magnitude. Therefore, these sensors can be considered as active resistance devices. Some particular cases are:

-

Piezoresistive sensors

-

Potentiometers (distance, position, angle)

-

Resistive temperature sensors

-

Thermistors

-

Photoresistors

-

Resistive hygrometers

-

Resistive gas detection sensors

-

Magnetoresistors

Capacitive

Capacitive sensors are devices where the physical quantity to be measured induces changes in the geometry or properties of a dielectric material, resulting in a modification in the sensor’s capacitance. In summary, capacitive sensors essentially operate as variable capacitors.

- Distance and position measurement

- Pressure, force, and acceleration measurement

- Humidity measurement, chemical analysis, and fluid level measurement

Inductive

Inductive sensors are devices in which the physical quantity to be measured causes alterations in the geometry or properties of a ferromagnetic material, resulting in a change in the sensor’s inductance.

- Distance, position, and thickness measurement

- Pressure, force, and acceleration measurement

Electromagnetic

In these sensors, the change in a physical quantity causes an alteration in a magnetic or electric field, without modifying the inductance or capacitance of the sensor. These sensors are based on Faraday’s law and the Hall effect.

Generating Analog Sensors

Generating analog sensors produce an electrical signal in response to the input physical magnitude. This type of sensor does not require external power and needs less wiring than modulating sensors. Generating sensors are divided based on the type of electrical signal they generate. In the category of generating sensors with electrical charge output, piezoelectric sensors and pyroelectric sensors are included. On the other hand, in the category of generating sensors with voltage output, thermocouples and ion concentration sensors are found.

Piezoelectric

Piezoelectric sensors exploit the generation of electric charges in a material when it is deformed under stress. Composed mainly of piezoelectric materials such as quartz, when force or pressure is applied, the material undergoes deformation. This process causes a redistribution of charge in the material, generating a positive charge on one side and negative on the other, with the net charge proportional to the applied force.

These sensors are used to measure mechanical quantities such as pressure, acceleration, and dynamic forces caused by vibration, oscillation, impact, compression, or tension. Although they have high sensitivity, the ability to detect high-frequency variations, and mechanical stiffness, they have significant limitations: they are sensitive to temperature and have a high output impedance, requiring an electrometric amplifier to condition their output signal.

Pyroelectric

Pyroelectric sensors are based on the generation of surface electric charges in a specific direction when a material experiences temperature changes due to the absorption of radiation.

These sensors have various applications, notably temperature measurement at a distance in industrial environments or assessing heat loss in buildings. They are also used to measure the power generated by radiation sources, detect gases that absorb infrared radiation, and detect people or animals through infrared radiation.

Generally, pyroelectric sensors are compact devices with high sensitivity to temperature changes. As they do not require thermal equilibrium with the radiation source, they have faster response times than thermistors and thermocouples.

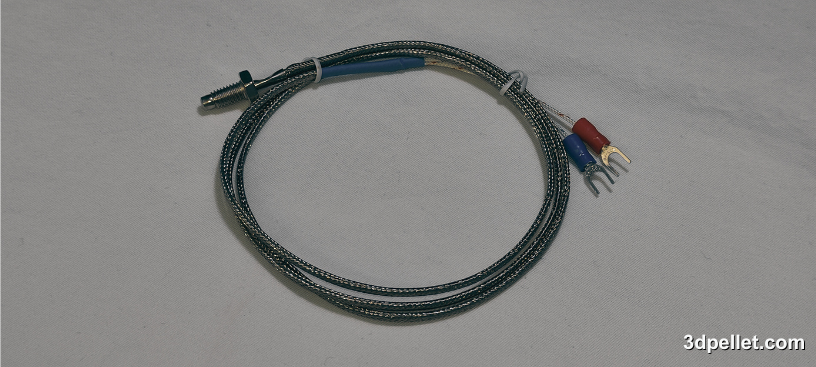

Thermocouples

A thermocouple is a temperature measuring device composed of two different metals joined at two points. Its operation is based on the principle of the Seebeck effect, which states that when the junctions of the two metals experience a temperature difference, a voltage proportional to this temperature difference is generated.

Thermocouples are widely used temperature sensors due to several advantages: they have a wide measurement range, from -270°C to +3000°C; they exhibit high stability and long-term reliability; they offer higher accuracy than resistive temperature sensors (RTDs) at low temperatures; they have a response time on the order of milliseconds; and since they do not require external power, they do not suffer from self-heating.

However, thermocouples also have limitations. Firstly, the conditioning circuit must ensure that the current flowing through the thermocouple is minimal to avoid measurement errors. Secondly, one of the two junctions must be maintained at a constant reference temperature. Finally, the response of the thermocouple is nonlinear, which usually requires signal conditioning correction.

Digital Sensors

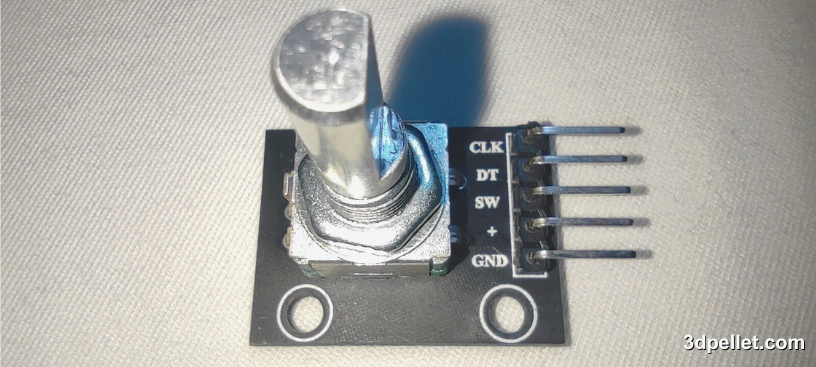

Digital sensors generate digital outputs directly from the physical input magnitude. Therefore, they do not require an analog-to-digital conversion stage. Among the most common digital sensors are position encoders, used to measure linear or angular displacements through physical contact.

Incremental Position Encoder

The incremental position encoder, used for measuring linear displacements, consists of two main parts: a static encoded tape or ruler and a movable sensing head that moves along with the object whose linear position is to be measured. The encoded ruler is divided into small sectors with distinctive properties. The movable head incorporates electromagnetic or optical sensors to detect the transition from one sector to another on the encoded ruler, resulting in a change in a digital output signal each time a fixed distance is traversed.

The incremental position encoder used for measuring angular displacements operates similarly to the linear one but instead of a ruler, it uses an encoded disk that moves along with the object whose angular position is to be measured. The encoded disk is divided into sectors, and each time the disk moves a fixed angle between two sectors, the head generates a change in a digital output signal.

Both types of incremental position encoders require additional components, such as a pulse counter (or similar) and a component to determine the direction of movement, to obtain the absolute position with respect to a reference position. This reference position is usually set by placing an end stop at the end of the encoded ruler. In case of a power interruption to the system, it will be necessary to move the sensing head back to the end stop.

Absolute Position Encoder

In the absolute position encoder, whether linear or angular, each section of the encoded ruler or disk is associated with a unique binary code. Consequently, the output of these encoders consists directly of an encoded signal representing the absolute position, whether linear or angular, with respect to a reference established by the sensor itself.

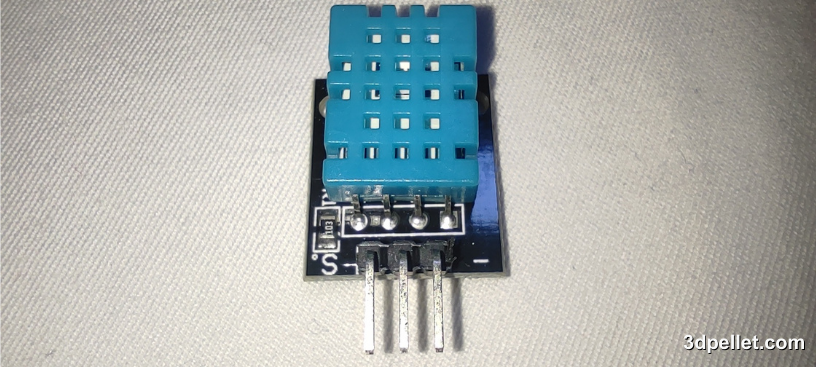

DHT11 Sensor with Arduino

Tutorial on the operation and utilization with Arduino of the DHT11 sensor

HC-SR501 Sensor with Arduino

Tutorial on the operation and use of the HC-SR501 PIR sensor with Arduino